Product prices, or stock prices, embody the costs for direct materials, direct labor, and manufacturing overhead. In a job-order costing system, product prices are assigned directly to the products or jobs as they are produced or accomplished. A supplies requisition kind tracks materials taken out of uncooked supplies inventory and placed in manufacturing. The information from both the materials requisition forms and timesheets is recorded on every job cost sheet. A job value sheet accumulates manufacturing prices for each job and serves as a subsidiary ledger for the work-in-process stock account.

What Does Activity-based Costing Search To Identify?

By integrating with different stock administration accounting platforms, these systems create a comprehensive organization of all tasks needed for any project. With at present’s expertise, corporations have access to powerful job costing software that may help them precisely track and report their expenses and earnings. Job costing software program allows companies to allocate prices to specific jobs or projects, giving them a comprehensive view of their operations and financials.

Manufacturing Firms

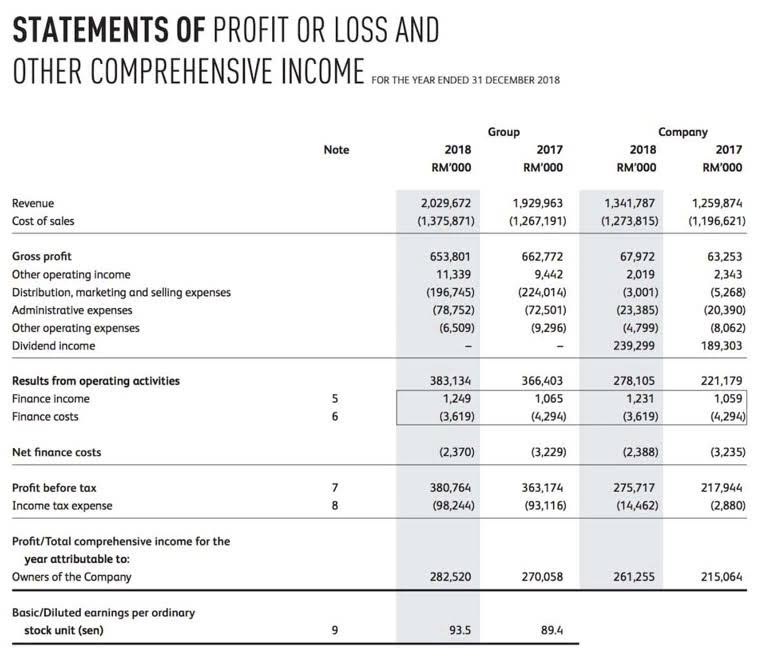

The software program may also be used to watch project progress and make adjustments. Cloud-based accounting software program has made subtle job costing capabilities accessible to smaller companies that previously couldn’t afford advanced techniques. These platforms provide real-time job profitability reports, price range versus precise comparisons, and automatic allocation of overhead prices. Prior to the sale of the product, separating production prices and assigning them to the product ends in these costs remaining with the stock.

Routine enquiries are normally acquired from clients relating to the technical features of a job and the worth to be paid by him. (iv) Absorption of overheads on the idea of predetermined charges is necessary which makes budgeting a prerequisite. (vi) Spoilage of material and faulty work may be recognized with particular job.

Activity-based costing (ABC) enhances the costing course of in 3 ways. First, it will increase the number of price swimming pools out there to assemble overhead prices. As A Substitute of accumulating all costs in one company-wide pool, it swimming pools prices by exercise.

- At the start of the period, the total quantity of producing overhead costs are estimated primarily based on historical information and current yr production estimates.

- The predetermined manufacturing overhead fee is computed earlier than the period begins, often firstly of a year or quarter.

- Job costing provides advantages extending beyond simple price accumulation.

- As A End Result Of overhead is initially applied to jobs based on an anticipated price, it is also essential to grasp the final disposition of under- or overapplied overhead.

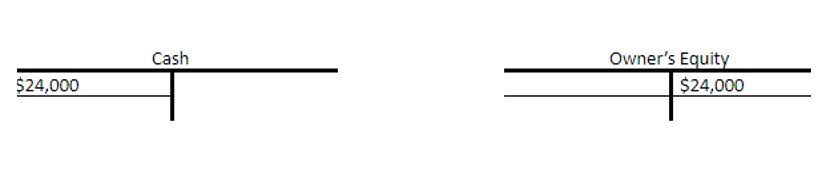

- This move of direct materials from one account to another is additional illustrated within the T-accounts that follow.

- Job price software program can aid in organizing bills and invoicing to ensure cash move is managed effectively.

The prices of such actions are traced to specific activities or merchandise. An intensive illustration is developed to demonstrate how time, material, and overhead is tracked and assigned. The chapter discusses how fashionable expertise has tremendously eased the burden and facilitated utilization of accurate job costing. Every furniture order turns into a separate job with its personal value accumulation. The producer tracks the value of totally different wooden species, hardware, stains, and finishes as direct supplies. Skilled craftsmen’s time is recorded as direct labor, whereas manufacturing unit overhead including tools depreciation, utilities, and facility costs are allotted to every job based mostly on labor hours or machine hours used.

Additionally, they could ask the accountants to extend the overhead utilized to jobs to give them a better concept of the value of jobs. If the precise is less than the applied overhead, they could ask the accountants to reduce the overhead utilized to jobs. The subsequent step is to post the knowledge proven on the timesheet to the suitable job cost sheet, simply as we did with direct materials. Exhibit 2-3 Formula for organization-wide predetermined manufacturing overhead price.

Once the allocation base is selected, a predetermined overhead rate could be established. The predetermined overhead rate8 is calculated previous to https://www.online-accounting.net/ the 12 months during which it’s utilized in allocating manufacturing overhead costs to jobs. Before multiple predetermined manufacturing overhead charges may be computed, manufacturing overhead costs must be assigned to departments or processes.

Assume of manufacturing overhead as a pool or bucket of all indirect product costs. At the beginning of the period, the total amount of producing overhead prices are estimated based mostly on historic data and present yr production estimates. All Through the year, the total amount of estimated manufacturing overhead is uniformly utilized to the roles in process using some type of allocation base or cost driver. An allocation base or price driver is a manufacturing activity that drives costs. Widespread allocation bases are direct labor hours, machine hours, direct labor dollars, or direct materials dollars. At the end of the 12 months, the estimated utilized overhead prices and precise overhead costs incurred are reconciled and any distinction is adjusted.

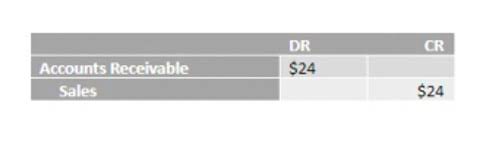

In a job-order costing system, value of goods offered represents whole production costs, e.g. direct materials, direct labor, and manufacturing overhead. Second, the manufacturing overhead account tracks overhead costs applied to jobs. The overhead costs utilized to jobs using job costing system a predetermined overhead fee are recorded as credit within the manufacturing overhead account. You saw an example of this earlier when $180 in overhead was applied to job 50 for Custom Furnishings Company.